PA hot melt adhesive film |

NAME: PA hot melt adhesive film

Description: This product belongs to the nylon material, accompanied by the debonding paper hot glue film, with high strength Degrees, high viscosity, for fabrics such as cotton, hemp, chemical fiber, have extremely strong viscosity, According to the different models, can be divided into high, medium and low temperature resistance, washing effect!

Application: PA hot melt adhesive film is widely used in automotive fabric, embroidered badges, all kinds of trademark, cut flowers, arts and crafts, shoes and hats and other textiles joint.

Main ingredients: polyamide

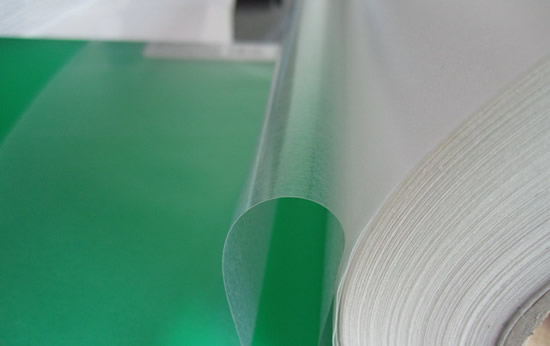

Product appearance: hot melt adhesive film layer + not viscose from type paper (rolled into a roll)

Regular width: 48 cm, 50 cm, 100 cm, 138 cm, 150 cm width can be customized

Conventional thickness: 0.06 mm, 0.08 mm, 0.10 mm, 0.12 mm, 0.15 mm and 0.18 mm

Each roll length: 100 yards, 200 yards, 300 yards, or according to customer requirements

Melting temperature: 80 ~ 90 ¡æ, 125 ~ 135 ¡æ

Ironing temperature: 110 ~ 120 ¡æ, 150 ~ 160 ¡æ

Press time: 10 ~ 15 seconds

Areas of application: high fastness of clothing trademarks, embroidered mark back glue; Strong fastness, high resistance to washing and dry cleaning requirements of textile goods adhesive... ..

Washing performance, good water resistance, resistance to water, 40 degrees 60 degrees Fahrenheit wash well.

Heat resistance performance: - 3 degrees to 90 degrees environment adhesive fastness is not change.

Objective evaluation: A62 film on fabric, fabric has the very good adhesive fastness and excellent resistance to washing, dry cleaning performance, rubber curing speed is easy to operation. Defect is sub slightly hard, is not very good low temperature resistance, such as in the environment - 10 degrees, rubber brittle.

1, will face toward the need of adhesive materials, iron, ironing machine, hot optional composite roller, high frequency, such as infrared heating apparatus equipment, through the protection paper heating, make glue surface melting, cement need sticky material surface.

2, cooling after tear protective paper, material surface with a layer of hot melt adhesive, then glue material C and need of adhesive material composite together, heating, cooling, both material and firmly bonding together.

3, may also directly bring a tear up the protection of the hot melt adhesive film paper directly and put rubber material and intermediate, heating, cooling after two materials and bonding together.

Choose hot melt adhesive film as a bonding agent, has the following advantages:

1, clean;

2, environmental protection;

3, fast effective - adhesive, a few seconds;

4, safe, no solvent, production process without operation risk;

5, hot melt adhesive for some materials particularly strong adhesive fastness, performance is superior to the glue;

6, it can realize automatic production, using hot laminating machine can achieve efficient large-scale production;

7, portable - material with glue for sale, and use it every time you feel you need just one hot, save for the glue, glue, glue coating of trouble;

8, can be repeatedly paste, hot melt adhesive once, can the heating stripping, stripping the product after, can again by heat bonding;

9, functional characteristics, hot melt adhesive are resistant to dry cleaning, washing resistance, good low temperature resistance, high temperature resistance and other kinds of hot melt adhesive selection;

10, can be used as adhesive and sealant used at the same time;

Choose the method of hot melt adhesive film and matters needing attention:

1, what is the material you need adhesive? Different material of hot melt adhesive, adhesive fastness of different material is different, is not that kind of glue for all materials adhesive bonding is greater than all the others, such as polyurethane fastness to textile fabrics is extremely strong, and the bonding strength of PE plastic is nearly zero;

2, your material the highest ability how much temperature of heating. Such as your highest heat resistance should not exceed 130 ¡æ, then you have to choose the hot melt adhesive melting point is lower than 130 ¡æ, because if the processing temperature of less than the melting point of glue, glue not melt, stick relay is almost zero;

3, you use adhesive products, whether to consider the soft? Whether to consider the application under high temperature or low temperature environment? Whether to pass water? If we need to dry cleaning? Whether to continue tensile tensile? If there is the above requirements, it will choose to have more than the corresponding performance of the film.

4, if there is a variety of adhesive can choose, choose the most cost-effective adhesive; In can meet the requirements of your bonding situation, choose the thinnest adhesive (glue the thinner, the lower the price).

5, call or online contact sea company sales personnel, can I help you choose the most accord with you need hot melt adhesive film products.